DESIGN DEPARTMENT

Technical advisors supporting

our customer efficiency

Our specialized advisors in Design Department work to offer our customer tailored solutions. Thanks to a consulting approach, we work out the best solution to improve the performance of the required component and increase its life whenever possible.

We manufacture custom-made components for various industries: starting from the customer’s need, we suggest the most effective solution for any application.

One of our distinctive elements in the preliminary study is the technical advice offered by our specialists. After an accurate analysis of working conditions, we fine-tune the project in close cooperation with our production manager and the customer’s technicians.

This results in high performing components, obtained through an accurate project definition and a careful production process.

OUR ORGANISATION

Tailor-made solutions

Our flexible internal organization is aimed at satisfying even the most complex request in a short time.

We design customized solutions either from an existing drawing or starting from the need of our customers requiring a thorough study.

Analyzing the working conditions of components allows us to customize our design, suggesting our customers the most convenient solution both for costs and performance.

This careful preliminary analysis carried out by our technical advisors is a strategic element for the success of our supplies: exchanging information with the customer all along the design and industrialization process we ensure the final output will meet the expectations.

OUR ORGANISATION

Tailor-made solutions

Our flexible internal organization is aimed at satisfying even the most complex request in a short time.

We design customized solutions either from an existing drawing or starting from the need of our customers requiring a thorough study.

Analyzing the working conditions of components allows us to customize our design, suggesting our customers the most convenient solution both for costs and performance.

This careful preliminary analysis carried out by our technical advisors is a strategic element for the success of our supplies: exchanging information with the customer all along the design and industrialization process we ensure the final output will meet the expectations.

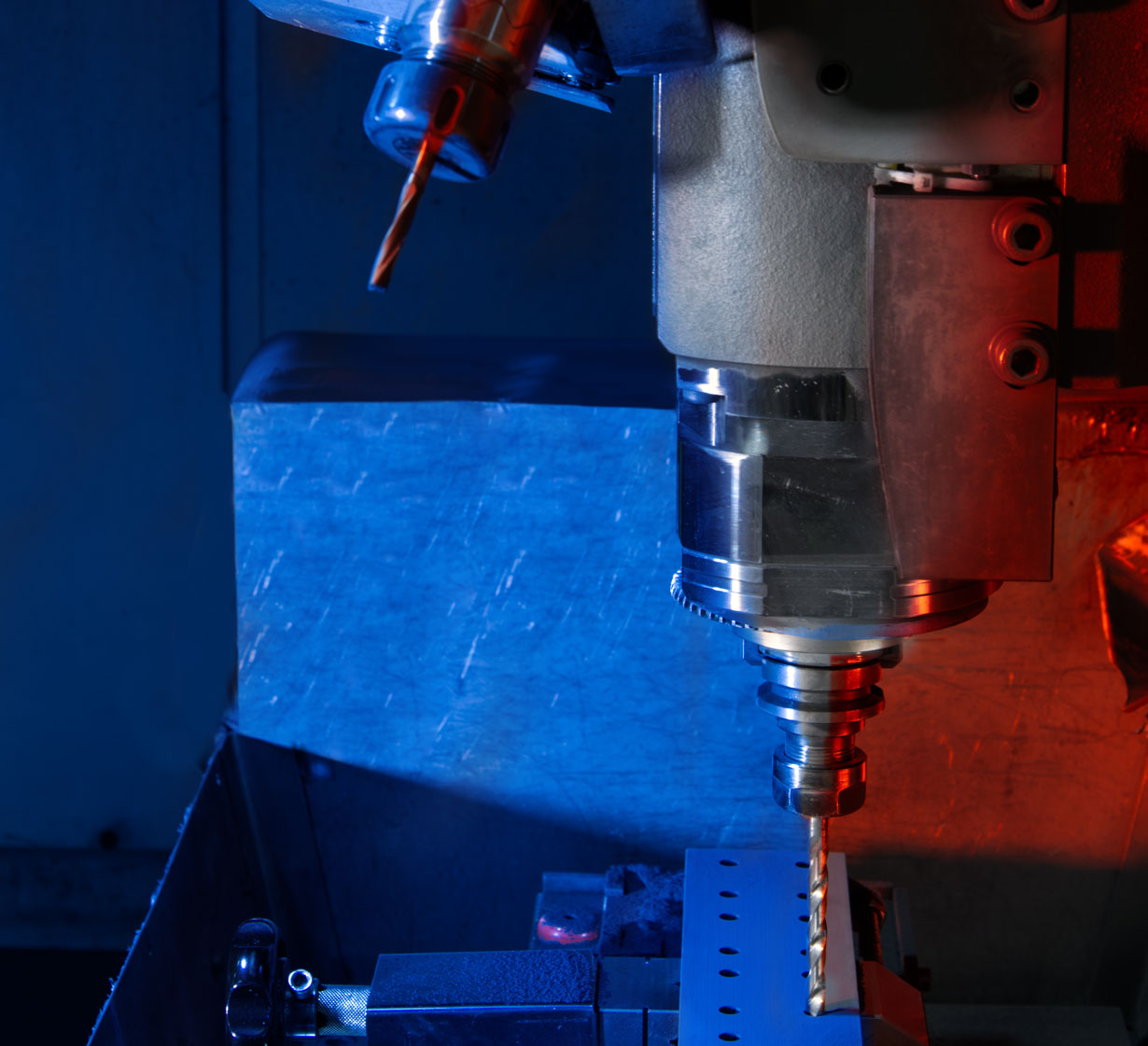

THE CHANGE

From steel to tungsten carbide

Aiming at always offering our customers the best solution in terms of costs and benefits, we work to suggest the transition, whenever possible, from steel to hard metal, or to a combination of the two.

When the working conditions allow it, in fact, we design solutions that considerably improve the performance and duration of the part through the use of a tungsten carbide insert where wear is more severe.

If feasible, we suggest in some cases to completely replace steel with hard metal, carefully choosing the powder mixture that better suits the application.

This passage often represents not only an improvement of performance, but also a double financial benefit: on one side, a reduced need of spare parts and on the other side a consistent drop of machine downtimes for maintenance and exchange of worn-out components.