OUR HISTORY

Expertise, innovation and quality since 1959

OUR HISTORY

Expertise, innovation and quality since 1959

Over 60 years of experience

In 1935 Augusto Geminiani was the first in Italy to work in hard metal sintering, together with Ingegner Brezzi, in a company called Adamas. After leaving the company in 1959, counting on his twenty-year experience, he establishes Sinterloy, in the same site in Castellamonte where it still is today.

Sinterloy consolidates its market position, serving several industries and obtaining important recognition, including “Mercurio d’Oro” and the important “Quality and Courtesy Award”. Augusto, already flanked by his sons Andrea and Giuseppe since a few years, gradually leaves the head of the company.

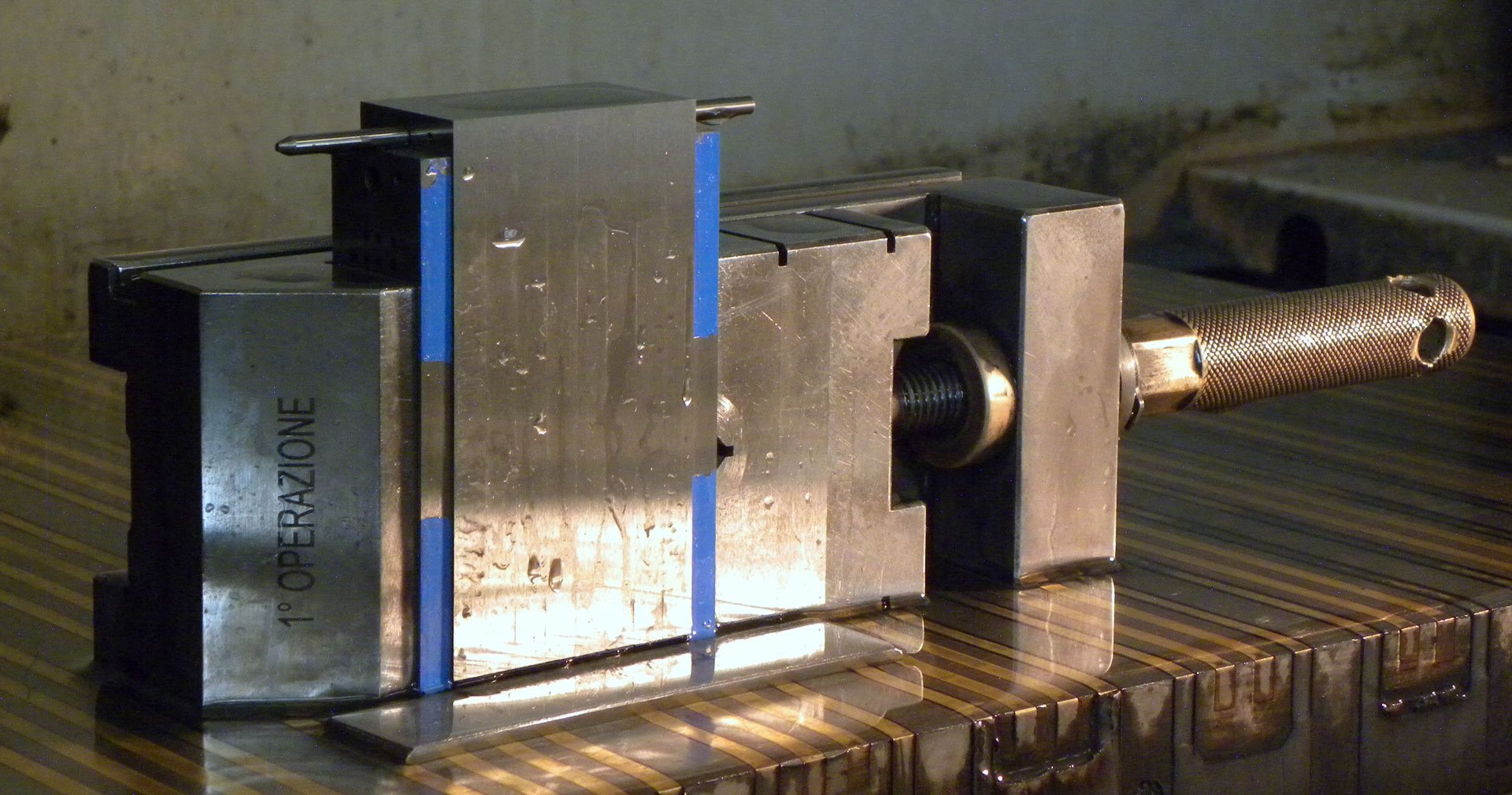

With the first extension of the original factory, Sinterloy develops an internal department entirely dedicated to grinding. In addition, the company invests on new technologies for powder pressing.

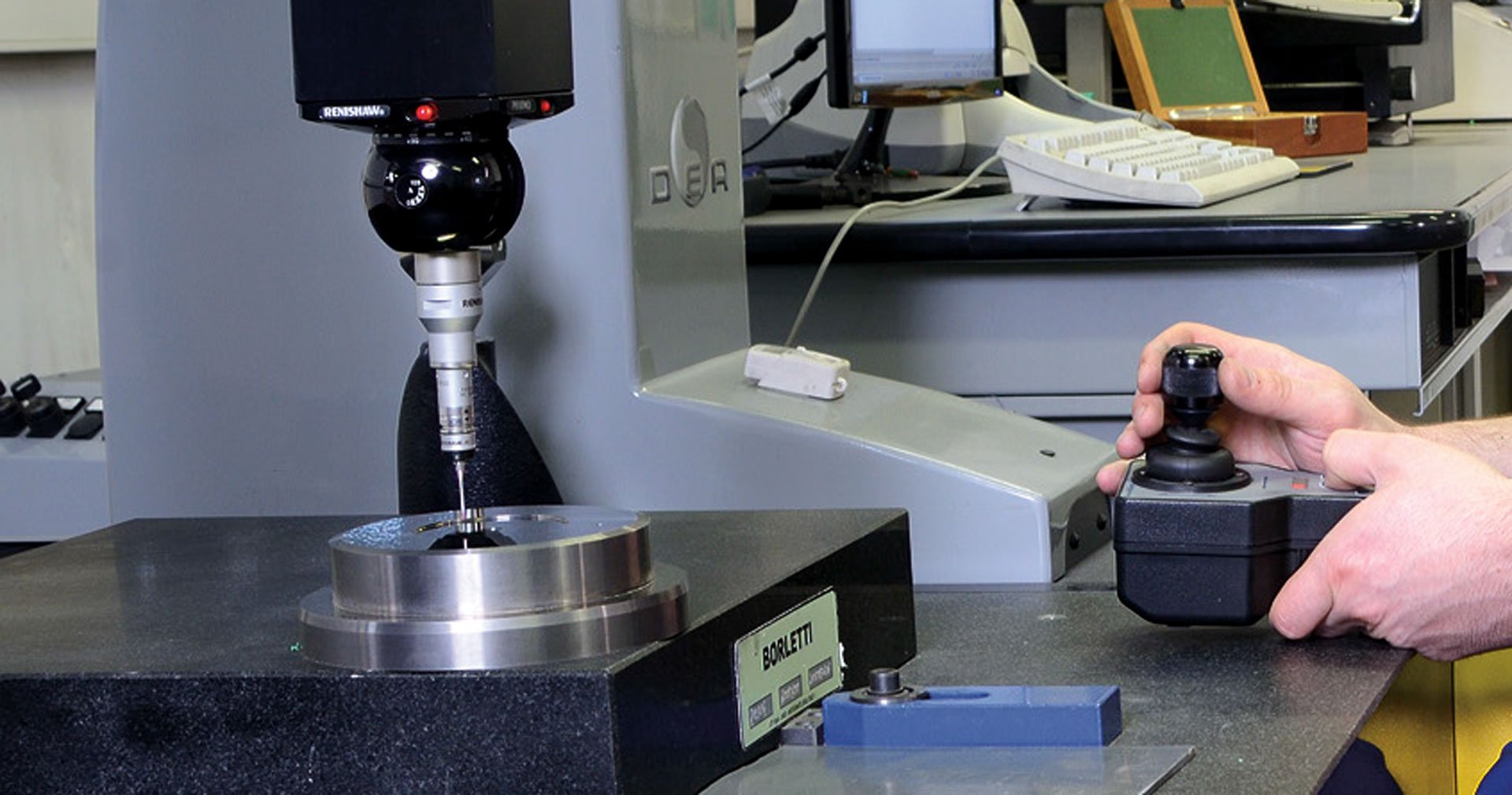

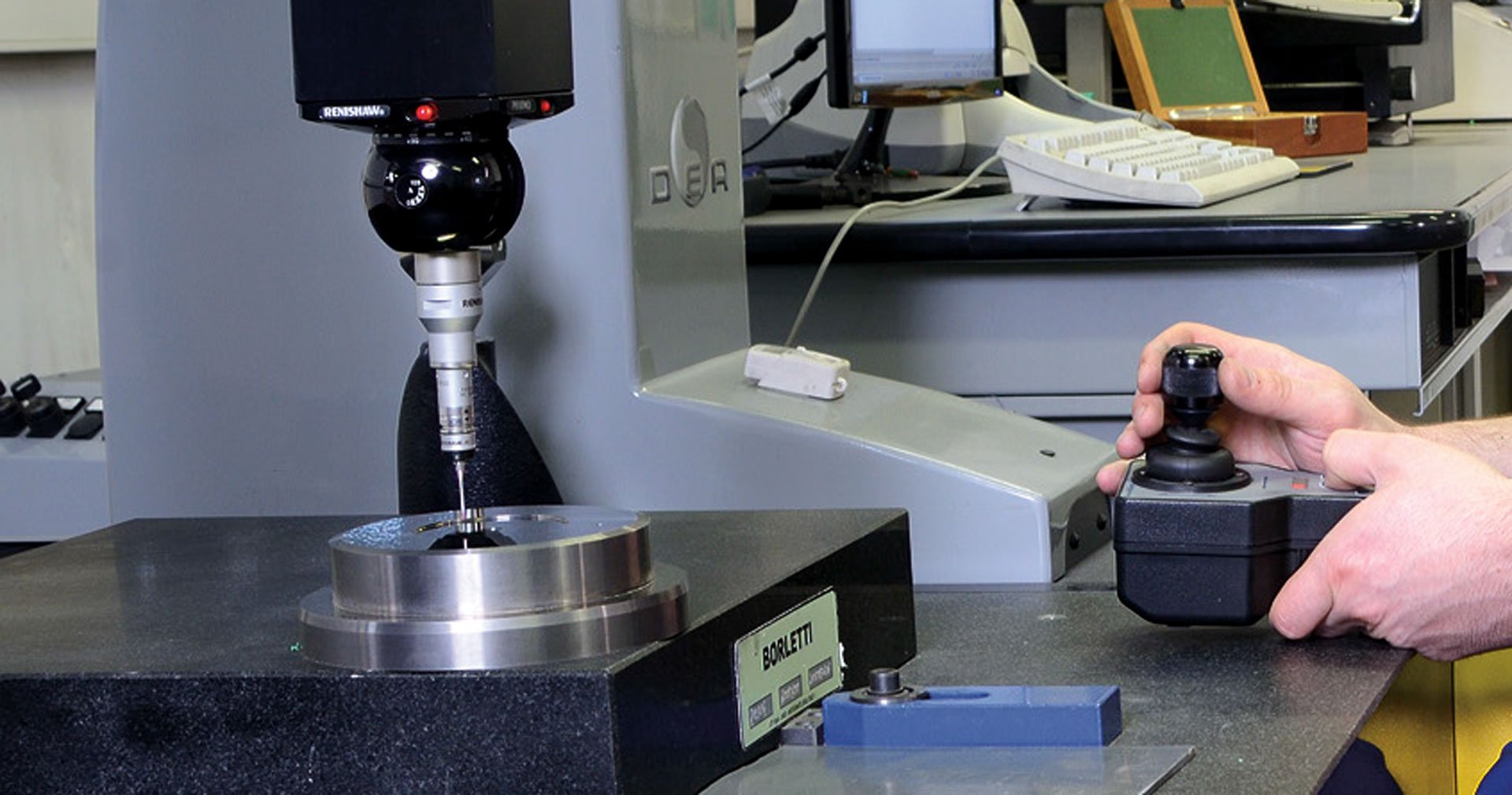

This is a decade of constant technology innovation: new equipment is added to the grinding department and more and more sophisticated measurement systems are implemented.

the second extension of the factory is completed and the total surface reaches 10.000 m2 - 3.000 m2 of which are covered. The company invests on an ongoing basis: new machines are implemented both in the production department and in the metrology lab.

Augusto, the grand-son of the founder, takes on the leadership of the business. Through renovation and further expansion of the production capacity, he revamps the company after the 2008 crisis. With the third generation firmly at the helm, the Geminiani family aims to consolidate its position on the foreign market, too.

Over 60 years of experience

In 1935 Augusto Geminiani was the first in Italy to work in hard metal sintering, together with Ingegner Brezzi, in a company called Adamas. After leaving the company in 1959, counting on his twenty-year experience, he establishes Sinterloy, in the same site in Castellamonte where it still is today.

Sinterloy consolidates its market position, serving several industries and obtaining important recognition, including “Mercurio d’Oro” and the important “Quality and Courtesy Award”. Augusto, already flanked by his sons Andrea and Giuseppe since a few years, gradually leaves the head of the company.

With the first extension of the original factory, Sinterloy develops an internal department entirely dedicated to grinding. In addition, the company invests on new technologies for powder pressing.

This is a decade of constant technology innovation: new equipment is added to the grinding department and more and more sophisticated measurement systems are implemented.

the second extension of the factory is completed and the total surface reaches 10.000 m2 - 3.000 m2 of which are covered. The company invests on an ongoing basis: new machines are implemented both in the production department and in the metrology lab.

Augusto, the grand-son of the founder, takes on the leadership of the business. Through renovation and further expansion of the production capacity, he revamps the company after the 2008 crisis. With the third generation firmly at the helm, the Geminiani family aims to consolidate its position on the foreign market, too.

Strong expertise and internationality

The best raw materials

Thanks to a long-established know-how on the selection of powders and important sintering capacities, Sinterloy can offer its customers durable, high precision tungsten carbide parts.

Decades of activity in the industry allowed the company to create longstanding relationships with the best international raw material suppliers, being thus able to ensure its customers the perfect powder mix for any application.

Sinterloy is amongst the most important manufacturers of sintered components in Italy and has extended its penetration abroad, becoming a trusted supplier to international companies.

Focusing on commercial development not only in Europe, but also in extra-European countries like United States, Mexico and Brazil, the export share has reached 30% of the global turnover.

The international development process is in continuous evolution thanks to an active commercial department operating on the areas with the highest potential.